There is no slot standard. Maximum material condition (mmc) is the size of a feature of size for which the part contains the maximum amount of material.

How To Apply Gdt To A Slot - Youtube

There is no depth to the larger hole since it only creates a bevel at the opening of the smaller hole.

How to dimension a slot bs8888. The first slot dimensioning method (a) provides the width and the distance between the end radii center points. Simply state width and overall length, and use an arrow to point to the slot’s object line. The square symbol is used in a manner similar to the diameter symbol.

Feature is a general term applied to a physical portion of a part such as a surface, hole or slot. The tolerance of the slot in figure 14.50 is.004 and the tolerance of the mating part is.002. Fos refers to any surface, or set of parallel surfaces associated with a size dimension.ex:

Solved slotted holes dimmensioning autodesk munity advance steel. You chose the one that works for you. Dimension value indicates the dimension is a reference value.

Slot hole dimension standard a pictures of 2018. Messy but clear (if that isn't an oxymoron). Full r vs drafting standards gd t tolerance ysis eng.

A hole diameter (a cylindrical surface), a plate thickness (two opposed parallel surface). Contents foreword iv 1 scope 1 2 normative references 1 3 terms and definitions 1 4 standards underpinning bs 8888 2 section 1: Allowance is the minimum clearance or maximum interference between parts.

Dimensioning of slots in solidworks for asme y14 5 legion. The length (horizontal dimension of the slot): Still not sure where autodesk got the list from.

For an external feature of size, the mmc size is the largest allowable size. If it (the 27mm dim) were not in a box, then i take it the drawing border tolerances would then apply. Delegates should be familiar with the conventions of engineering drawing, such as projections, cross sections.

Solved re center line of a slot ptc munity. For the slot example i decided that if i didn't know what le meant then how can i expect my reader to know. The british standards institution (“bsi”) takes your privacy very seriously and respects the importance of security on the internet.

To confirm the status of any standard, identify the replacement standard if it is obsolete and/or purchase the standard please use bsi shop.it is also possible to become a bsi member and obtain copies of the standards at much reduced prices. When the mmc modifier is used, it indicates that the specified. Dimensioning, continued countersunk countersunk (csk) and counterdrilled holes (cdrill) are two holes drilled and at different depths that share a common center.

For countersunk holes, counterdrilled holes specify the diameter and the included angle of the countersink. For an internal feature of size, the mmc size is the smallest allowable size. Shown by the toleranced dimension.

Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). The scheme chosen for position tolerance is legal as well. Technical product documentation 4 5 types of documentation 4 6 drawing sheets 4 7 title block 7 8 scales 10 9 general tolerances 10 10 conventions for arrangement of views on a tpd 12 11 mechanical engineering drawings 15 12 diagram 17 13 lines, arrows and terminators 18

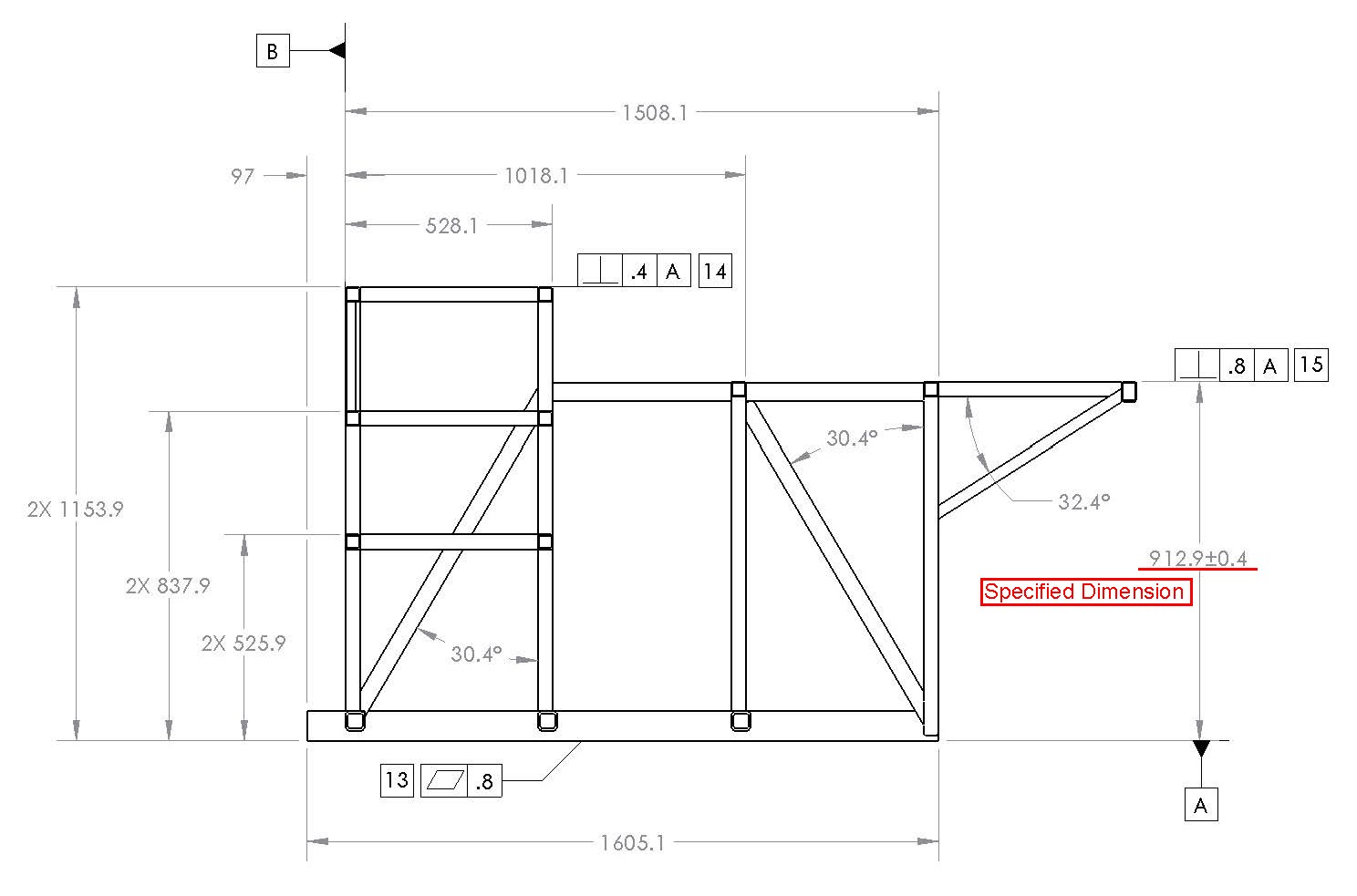

Following the logic of using slots, this feature has the highest tolerances. The drawing does indeed refer to asme y14.5m (2009). Look at the enclosed picture.

These pages include various standards. Dimension checks are made at the shear area or “cut band” (punch side) as the die side accuracy is affected by break out. This section introduces the dimension calculations for spur gears, helical gears, gear rack, bevel gears, screw gears, and worm gear pairs.

I ended up dimensioned the heck out of the multiple slots at different sizes on my part. All 3 way to dimension the slot are legal, although the one in the middle sometimes is recommended for slots punched in sheet metal. Tolerance is the total variance in a dimension which is the difference between the upper and lower limits.

Geometrical dimensioning & tolerancing to bs 8888 and iso standards: Method (a) the second method (b) is the easiest and simplest to dimension. Bsi websites use cookies and similar technologies for various purposes including to distinguish you from other users of our websites.

Gd t best practices 2016 04 01 quality. This has a feature size tolerance of ±0.5 mm and a position tolerance of 0.8 mm at mmc with respect to datum reference frame abc.

Chapter 7 Dimensioning Contents Introduction Dimensioning Components Their

Dimensioning Of Slots In Solidworks For Asme Y145 Solidworks Legion

Httpwwwstaffcityacukra600me1105lecturesme1110-05pdf

Chapter 19 Threaded Fasteners Engineering Drawing 2nd Edition Dev Guis

The Essential Guide To Technical Product Specification Engineering Drawing Colin Simmons And Neil Phelps - Pdf Free Download

Dimensioning Of Slots In Solidworks For Asme Y145 Solidworks Legion

Dimensioning Of Slots In Solidworks For Asme Y145 Solidworks Legion

Full R Vs R - Drafting Standards Gdt Tolerance Analysis - Eng-tips

Dimensioning Standards Rules And Practices Accurate Dimensioning Is

Types Of Dimensioning Vibadirect

Dimensioning And Locating Advanced Features

Httpwwwstaffcityacukra600me1105lecturesme1110-05pdf

Httpsnanopdfcomdownloadobservation-record-engineering-drawing-cad-and-design_pdf

Httpwwwstaffcityacukra600me1105lecturesme1110-05pdf

Httpwwwstaffcityacukra600me1105lecturesme1110-05pdf

Drilled Hole - An Overview Sciencedirect Topics

Httpwwwstaffcityacukra600me1105lecturesme1110-05pdf

Httpwwwstaffcityacukra600me1105lecturesme1110-05pdf